Checklist for preventive maintenance on the fly

Every field service technician is familiar with maintenance equipment checklists. Let’s see why.

Every equipment under your care has a different maintenance plan. Not just schedule. Let’s take a battery, for instance.

An industrial battery requires preventative maintenance at periodic intervals. If in heavy use, then as frequently as every month. Preventive maintenance (PM) is done to ensure one does not need to come back for ad hoc maintenance/ repair for damaged batteries- basically the same principle behind PM that is followed for all equipment.

Now, every equipment that needs maintenance requires a checklist for preventive maintenance for the technicians to follow. Be it an automobile or a fuel pump or a battery. This is common sense as well as common practice. These maintenance equipment checklists can run to 5/ 6 items for simpler items like a battery vs hundred or more for an automobile.

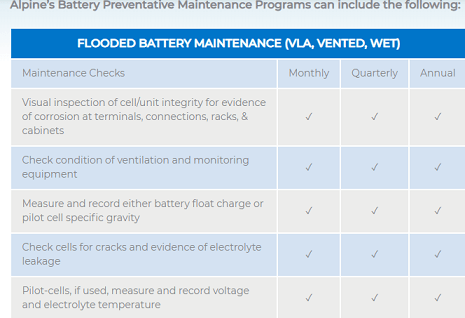

As an example, take a look at the maintenance equipment checklist published by Alpine Power Systems.

Till recently the technicians went around with printed maintenance equipment checklists and noted their finding there.

The problem with maintenance equipment checklist so far

Committing your checklist for preventive maintenance to a paper based strategy has obviously 2 problems.

- Paper is tough to track, and audit. End of the day, someone needs to (or should) sit down with the sheaf of papers documenting all the PM activities that have happened that day and check if the right procedure was followed. Were the right observations made, corrective actions taken and customer feedback monitored?

In comes software. Mobile and web based. For capturing records for every maintenance activity performed. And being able to draw appropriate lessons from the past activities. So, obviously, maintenance equipment checklist should be the first to be computerized.

2. And, keeping history, maintaining records and learning from experience is near impossible unless you have a process for transcribing (error free) all the filled up maintenance equipment checklists. Regularly. And, have a software for analysing the historical records for trends to be wary about.

Challenge with computerizing maintenance equipment checklist

Then comes the challenge: do you have to have different software for maintaining, say a laptop than for maintaining a washing machine? Or for a diesel generator set? Because the preventive maintenance checklist to be used for capturing the details regarding each type of equipment is very different, as you can understand.

Or, should you custom develop- with the help of your software vendor, a checklist for preventive maintenance for the equipment that you maintain? And, look for him again when the firm needs even a minor tweak?

Not easy huh?

That’s where Saleswah CRM comes in.

Checklist for preventive maintenance: Mobile app driven totally customizable

We provide you the ability to custom design, not one, but scores of product category maintenance equipment checklist – one for each type of products you have under maintenance. Not just that; you can create custom forms for visits – as well. These checklist for preventive maintenance are available instantly to all users once designed by the admin.

But, hold on. When you have scores of forms with you on your mobile app, that’s just the same as carrying around multiple paper forms for different product types, right? Ah, no. Saleswah CRM is smarter than that. When you are attending to a an equipment under maintenance, the software will show ONLY the relevant form to you. Without your intervention. In fact, you can’t pull up a wrong form even if you tried.

All this works- without a single line of code, any need for “implementation consultants” getting involved and any spend on time and money.

If you would like to have a demo of how to create maintenance equipment checklists – contact us for a demo.

Saleswah CRM is being used for field maintenance of about 35000 Diesel Generator Sets by a customer. Many of these DG sets are located in remote parts of India. They are installed in Telecom Towers for providing backup power.

Saleswah CRM is being used for field maintenance of about 35000 Diesel Generator Sets by a customer. Many of these DG sets are located in remote parts of India. They are installed in Telecom Towers for providing backup power.