Scheduling preventive maintenance of equipment in regular intervals is required to ensure the trouble-free operation of equipment. This is especially applicable to mechanical equipment- even more so to those with an engine inside.

Moving parts means wear and tear. So, periodically one may need to replace worn-out parts, replace consumables, and so on. We all take our car to the garage for servicing at least once a year- and are familiar with the replacement of lube oil, air filters, fuel filter, and so on.

Of course, there is some equipment which needs maintenance even without there being a moving part in them. A lead-acid battery needs frequent topping up, sometimes once every 3 months.

There are 2 types of scheduling preventive maintenance of equipment- largely governed by the type of equipment.

Fixed interval scheduling preventive maintenance

this happens when the equipment is required to be maintained at a fixed interval of, say, a year or 3 months or some such interval. This typically is for equipment without moving parts or where an assumption regarding wear and tear is made over a timeframe.

Variable interval scheduling preventive maintenance

This happens when the scheduling needs to happen at a variable interval. Here the scheduling accounts for the wear and tear that may happen. Basically, the principle is- if the machine is running daily for a long time, then the maintenance needs to happen sooner than if the machine was hardly being used. Think of the automobile again. Typically, we get our cars serviced once a year. But a rental car – which runs a thousand kilometers per week- will be due for service in a couple of months.

Why do we need to depend on computers?

Let’s say you are managing service operations for equipment spread over a large geography and they are not easily accessible or their readings can not be noted regularly. In that case, there is no option but to rely on past data to make predictions about the future. Let us say, a machine requires preventive maintenance after 1000 hours of running, and let’s say it has run 500 hours to date since the last service, we must look at the data and check how many hours it is running on an average every day and extrapolate it from there to schedule the next service due to date.

How do we decide the variable interval in scheduling preventive maintenance?

Luckily we don’t. Computers do. But we do write the algorithm. In algorithmic scheduling preventive maintenance, the past is the determinant of the future.

Algorithmic scheduling of maintenance is an area of research. Some of the algorithmic scheduling is quite complex. Here’s a research paper that deals with modeling this activity at some length.

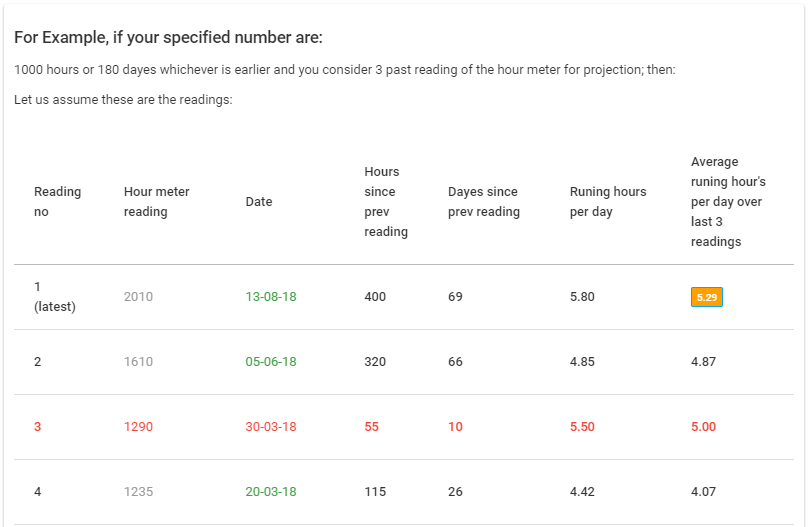

We have used a simple algorithm based on moving averages for scheduling preventive maintenance for equipment that are installed in remote locations.

How does algorithmic scheduling preventive maintenance really work?

Step 1: we need to note the run hours the machine has logged since the last visit. This we do on every visit. And this gives us the average run hours. And we calculate this over the last three or five visits.

Step 2: Then we extrapolate. Let us say a machine is due for maintenance after running for 800 hours. Now let us say that we have found that a machine is running on an average for 10 hours a day (as calculated). We say that if the machine has been running on an average for 10 hours a day, and it was due for maintenance in 800 hours, then it is going to be due for maintenance in 80 days from the last maintenance. Makes sense, does it not?

Why this works

The beauty of this is, because we are working with moving averages, we are able to achieve very good results with scheduling preventive maintenance. This technique is used especially when we have equipment under maintenance which are in far flung areas and we are not able to access the actual run hours data on a daily basis.

For an example of where we have used this, read the DG set case study.